For roofing contractors, one of the most critical project decisions is whether the right items are being ordered, in the right order, to keep crews moving. The difference between roofing supplies and roofing materials has direct consequences for scheduling, labor costs, and customer satisfaction. When the correct components don’t arrive on time, labor hours are wasted and schedules begin to slip.

Industry experts highlight that mislabeling, delayed deliveries, and mishandled materials are all common logistical problems that can interrupt roofing workflows and turn a straightforward job into a costly delay (metalink.com.ph).

If you’re searching for roofing supplies in Florida, SYL Roofing Supply has built its service model around keeping crews on schedule, with practical delivery and support options for contractors statewide.

The Simple Difference Between Roofing Supplies and Roofing Materials

It’s a question nearly every contractor faces: what’s the real difference between supplies and materials, and why does it matter so much for project planning?

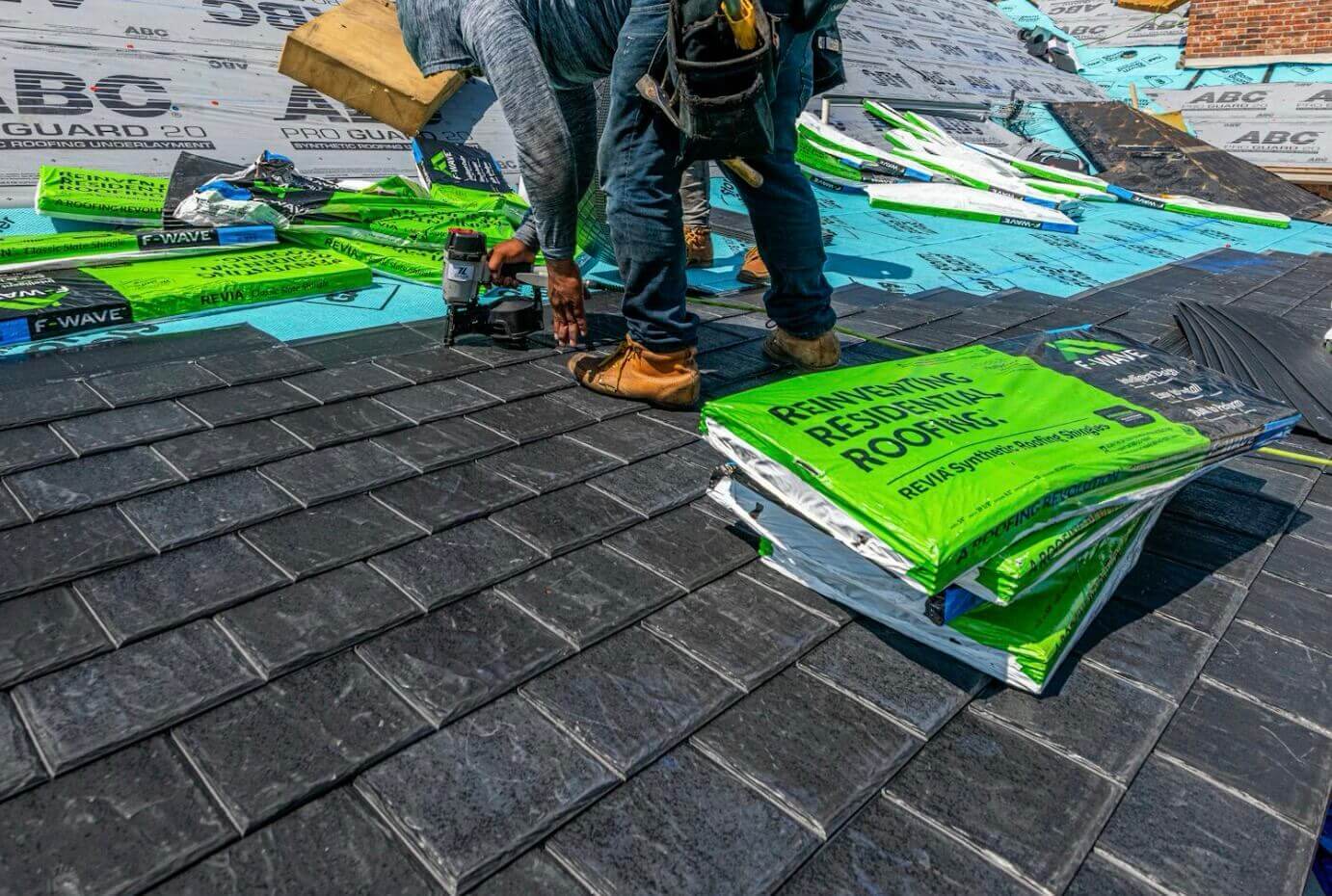

Roofing materials are the primary components that form the roof’s structure and surface—think shingles, tiles, underlayment, and metal panels. Roofing supplies, on the other hand, are the essential accessories: fasteners, adhesives, tools, and safety equipment.

For Florida contractors, this often means sourcing code-compliant asphalt shingles, metal roofing, or TPO systems to withstand hurricanes, while supplies include hurricane-rated fasteners, adhesives, and inspection-ready safety equipment.

Failing to differentiate between the two can mean crews are left waiting for missing items, or jobs are held up for a single, overlooked component. Industry literature and contractor experience both underscore that meticulous material management is critical to keeping jobs on track (metalink.com.ph).

What really matters is that confusion here is a leading cause of wasted labor hours and project delays—making clear, organized ordering a must.

Order First: Building Your System Baseline

When it comes to roofing project sequencing, the “system baseline” comes first. This means ordering the core materials your project relies on, such as underlayment, shingles or panels, ventilation, and the right fasteners—all matched to your roof type.

System baseline categories differ: asphalt shingles for pitched roofs, TPO for low-slope projects, or metal panels for durability. Florida’s strict permitting means DBPR code-approved materials are often required.

Why does this matter? Industry data shows that 55% of roofing contractors cited delayed shipments as the primary challenge in completing projects on time in 2023 (gitnux.org). Supply chain disruptions, especially around key system materials like underlayment or asphalt shingles, can halt a project before it even begins.

The global shortage of asphalt shingles affected 75% of roofing projects in North America in 2022, leading to widespread delays (gitnux.org).

To avoid these issues, always coordinate with your supplier about lead times and order these essentials as early as possible. For a complete look at category options, you can browse roofing materials to match your next project’s baseline needs.

Order Next: The Delay-Prevention Supply List

Even with the main system components staged, projects often grind to a halt over the “small stuff.” Fasteners, sealants, ventilation accessories, and tools frequently go overlooked until the last minute.

Supply chain disruptions have made these items particularly vulnerable to unexpected shortages in recent years.

Shortages of fasteners and adhesives are a top cause of jobsite slowdowns.

Inaccurate quantity takeoffs—like underestimating insulation boards or missing site wastage—can leave crews idle while they wait for a merchant to deliver forgotten items (builderexpert.uk).

This is why professionals always double-check their supplies list before confirming an order.

How to Stage the Order for a Fast Crew Start

A well-staged order is what separates organized crews from those scrambling at the last minute. Here’s how to ensure your materials and supplies are ready for action:

- Group by Installation Sequence: Bundle materials by roof section and install step, so nothing is missing when the crew moves from tear-off to install.

- Label and Protect: Clearly mark bundles, and use weatherproof coverings if rain is a risk.

- Check Quantities and Access: Verify on-site storage space and that you have all fasteners, adhesives, and tools needed for the day’s work.

- Leverage Digital Tools: Roofing software with project management features is essential for keeping track of orders, supply status, and material quantities. Efficient project management leads to smoother operations and higher profitability (leaptodigital.com).

Industry best practices also include grouping by delivery route and validating all items on arrival to prevent mix-ups and delays.

Delivery vs Pickup: Choosing the Fastest Fix for Missing Parts

When a key item is missing, should you send someone to pick it up, or schedule a rapid delivery? Both options have tradeoffs, and the best choice depends on urgency, order size, and crew availability.

| Delivery | Pickup | |

|---|---|---|

| Time Impact | May require waiting for next available slot | Immediate if nearby, but pulls crew member |

| Cost | Often included, but may have minimums or fees | Labor cost of pulling a crew member |

| Control | Supplier manages logistics | Contractor manages the run |

| Risk | Weather or traffic delays supplier | Crew member may get delayed |

In 2023, 55% of roofing contractors identified delayed shipments as the primary challenge in completing projects on time (gitnux.org).

Sometimes, the quickest route is a quick pickup for a small, urgent need; for larger or planned needs, roofing material delivery is usually more efficient and keeps your crew focused on the job.

In Florida, weather unpredictability adds another layer of urgency to every delivery or pickup decision.

Best Practices and Red Flags: Keeping Projects on Track

Too many teams focus only on the big-ticket items, forgetting the small details that can derail a project. Here are a few rules and warning signs every contractor should know:

Key takeaway: Meticulous order planning and supplier communication are your best defenses against lost time and cost overruns.

Unusually low quotes or vague estimates may signal substandard materials or poor communication—issues that can lead to project headaches and unhappy clients (leaptodigital.com).

Always confirm your supplier’s credentials, licensing, and delivery practices before placing an order.

Working with unlicensed or uninsured suppliers can expose contractors to major legal and financial risks, especially under Florida’s strict regulatory environment.

Technology and Trends: The Future of Roofing Supply Management

When it comes to roofing supply chain management, digital project management tools are becoming the new normal—especially as supply chain disruptions and cost pressures grow. The construction industry has seen input costs rise nearly 39% since early 2020, and delivery timelines have expanded dramatically (premiercs.com).

Roofing companies using digital tools to track orders, manage inventory, and communicate with suppliers are better positioned to avoid delays, control costs, and keep their crews productive (leaptodigital.com).

In fact, 78% of roofing companies now use digital technology to streamline everything from order tracking to client communications.

References

- BuilderExpert.uk. (n.d.). Cost of Inaccurate Construction Estimates. https://builderexpert.uk/cost-of-inaccurate-construction-estimates/

- LeapToDigital.com. (n.d.). Common Roofing Mistakes. https://leaptodigital.com/blog/common-roofing-mistakes/

- Metalink.com.ph. (n.d.). Common Roofing Issues That Delay Construction Projects. https://metalink.com.ph/blogs/common-roofing-issues-that-delay-construction-projects/