In Florida, storm season is more than just a forecast—it’s a challenge that tests the planning and supply strategies of every roofing contractor. When hurricanes and severe storms arrive, job schedules tighten, material demand surges, and crews must adapt quickly to stay on track. For contractors and builders, effective roofing supply storm season strategies and precise material staging are essential for keeping projects moving. SYL Roofing Supply stands out as a trusted partner, supporting professionals with fast delivery options, bilingual service, and a mobile app designed for jobsite efficiency.

If you’re tired of last-minute delays and want to keep your crews moving, it’s time to rethink how you stage and source your materials with a reliable roofing supply in Florida.

What Changes During Storm Season in Florida

Storm season in Florida adds layers of complexity—tight weather windows, site access challenges, and unpredictable material shortages. Contractors are forced to navigate increased demand just as storms disrupt transportation and supply chains, making proactive planning essential. Adding to the pressure, roofing material costs surged by 30% in early 2025, making accurate budgeting and procurement even more critical (floridaroofers.org).

Even well-run projects can hit snags: in 2024, 35% of Florida contractors identified project delays caused by availability and supply chain disruptions as a major concern. Hurricanes have historically delayed construction projects by an average of 24 days (agc.org; workyard.com).

This means that every schedule, delivery, and material list needs extra scrutiny as storm season approaches.

The reality is that storm season roofing logistics will test your processes and your partnerships, especially in hurricane-prone Gulf Coast regions, so contractors who plan ahead are the ones who stay ahead.

The Staging List That Protects Schedules

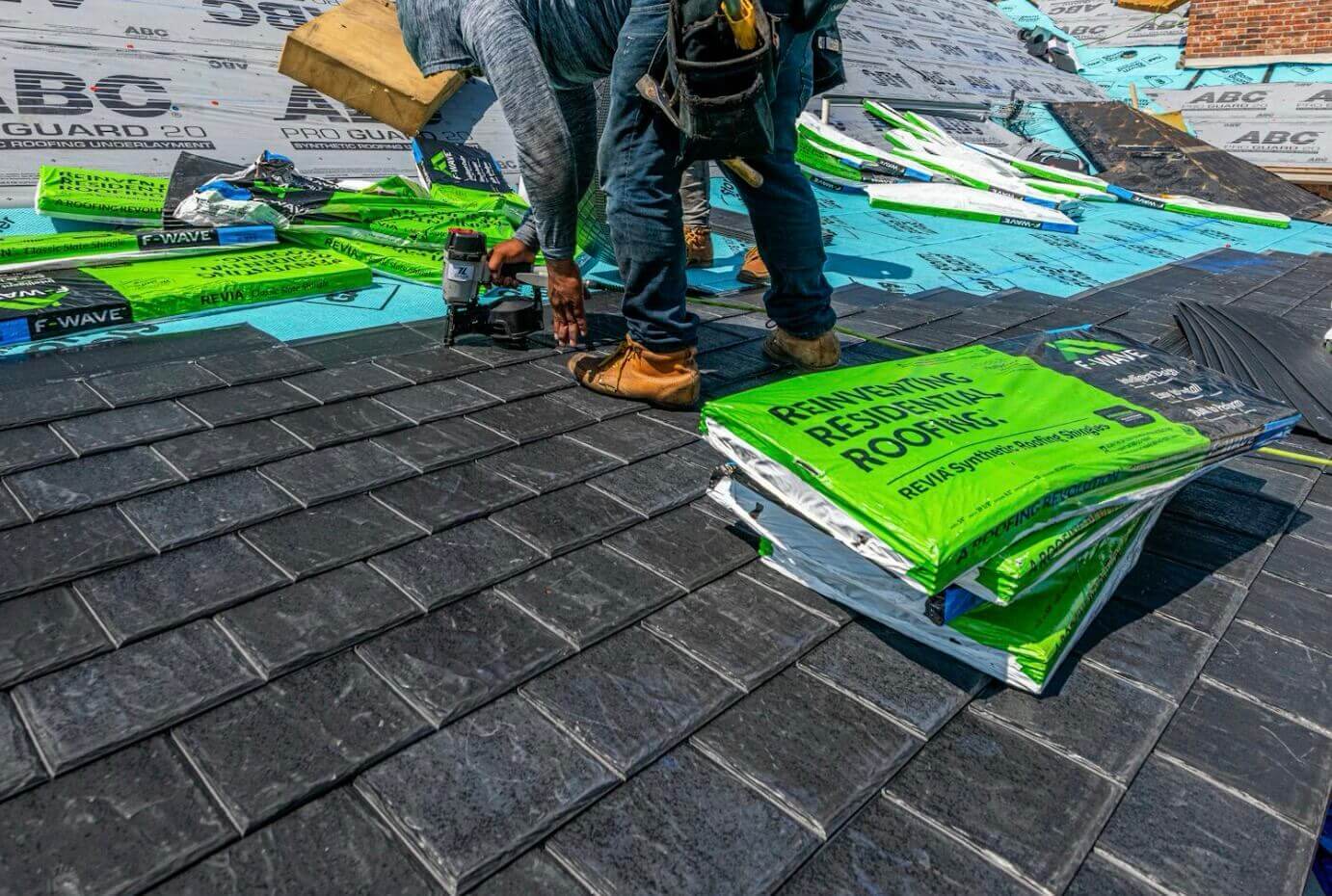

A well-prepared staging list is the backbone of a smooth storm-season roofing job. Start with the essentials: shingles, underlayment, fasteners, sealants, ventilation components, and tools. These categories cover the core needs for most Florida installations and help guard against weather-driven interruptions.

Roofing companies often face challenges with the availability of essential materials like shingles, underlayment, and flashing during storm seasons, which can lead to project delays (blog.originexteriors.com).

When you’re building your staging plan, don’t overlook “stop-the-job” accessories. These are the items—like specific fasteners or specialty sealants—that, if missing, can halt progress and force expensive return trips. Ventilation pieces and specialty sealants are frequently cited as items that delay jobs if not staged in advance.

After you’ve checked your list, browse roofing materials to confirm every category is covered.

This approach to roofing material staging helps you avoid costly oversights and keeps crews working.

The best contractors treat staging as a discipline, not an afterthought, because roofing material shortages storms can upend even the best-laid plans.

While just-in-time inventory methods are common in roofing, they can leave crews especially vulnerable to storm-related supply shocks.

How to Build a Compatible Set for Each Job

Why does matching your system and accessory categories matter so much during storm season?

It’s a common scenario: a job starts with everything seemingly ready, but progress stalls because a specific type of fastener or vent isn’t on hand. This slows the crew, increases costs, and creates frustration for everyone involved.

Mistakes in construction—often due to improper material matching or missing accessories—can result in costly rework and delays (floridahardhatlaw.com).

Best practice? For every job, confirm that your chosen system (shingles, TPO, or metal) is paired with all required accessory categories: underlayment, fasteners, ventilation, and sealants.

This is the core of roofing supply staging best practices and saves time, reduces callbacks, and keeps your operation moving efficiently.

And if you’re unsure, SYL’s bilingual experts are available to help contractors choose compatible materials for any job.

Delivery Planning That Prevents Downtime

Careful, proactive delivery planning keeps jobs on schedule—especially during storm season. Here’s how to build a process that works:

- Assess Site Access and Drop Zones: Identify the best place for deliveries, making sure materials won’t be exposed to the elements or block workflow.

- Schedule Deliveries for Flexibility: Take advantage of SYL’s same-day delivery or next-day delivery options (roofing material delivery), aligning drops with tear-off and install days to minimize material exposure and crew downtime. For jobs facing particularly tight windows, consider scheduling a Saturday delivery or using SYL’s express pick-up options to avoid weather-related hold-ups.

- Designate Who Receives and Stages Materials: Assign a crew member to check deliveries and move materials to protected areas.

- Weatherproof and Organize: Use tarps and elevated storage methods to keep materials dry and accessible.

- Build in Buffer Time: Permit-related issues account for about 35% of commercial roofing project slowdowns, and even tool management can cost a jobsite a day per month (linkedin.com; gocodes.com).

Many contractors now use mobile apps to track deliveries and coordinate scheduling—SYL’s app keeps job info, orders, and invoices at your fingertips.

Good delivery planning means less scrambling and more productive days.

Storm season roofing logistics and roofing supply chain disruptions storms can’t be avoided, but they can be managed with a structured, repeatable process.

The One-Page Storm-Season Checklist

Visual clarity beats guesswork—here’s your quick-hit storm-season readiness checklist:

- Access & Contact: Confirm site access details and provide updated contact info for all key personnel.

- Staging Area: Identify and mark the area where materials should be stored and protected.

- Inventory Check: Review your staging list to confirm all core system materials and accessories are present.

- Protection Plan: Prepare coverings and weatherproofing solutions for all materials, especially underlayment and fasteners.

- Emergency Plan: Establish a clear protocol for material shortages or delivery issues so crews know how to respond.

- Code Approvals: Confirm all necessary permit documents and code compliance are ready for inspection.

Industry insights consistently show that roofing companies who use pre-storm checklists and routine inspections are better equipped to handle last-minute surprises and keep jobs moving smoothly—even when the weather doesn’t cooperate.

Routine inspections can also extend the life of your roofing system and reduce the risk of emergency repairs after a storm.

Don’t skip this step: browse roofing materials and update your checklist before every storm season.

Roofing crew scheduling storms and smart roofing project management storm season practices start with a clear plan.

Conclusion / Call to Action

Storm season will always put Florida contractors to the test—but with the right roofing supply storm season approach, your jobs don’t have to fall behind. Proactive staging, tight delivery planning, and a disciplined checklist can keep your crews productive, your schedules intact, and your clients satisfied.

SYL experts can also help you navigate Florida’s code approval and permitting processes, giving you one less thing to worry about this storm season.

Ready to get ahead of the next storm? Schedule delivery, consult with the SYL experts, or use our app to streamline your orders and keep your business moving all season long.

References

- Workyard. (n.d.). How Weather Impacts Construction Projects. https://www.workyard.com/construction-management/how-weather-impacts-construction-projects

- Florida Roofers Association. (2025). Roofing Material Costs Surge 2025. https://floridaroofers.org/roofing-material-costs-surge-2025/

- Origin Exteriors Blog. (2025). What Challenges Do Roofing Companies Face During Storm Damage Repairs? https://blog.originexteriors.com/what-challenges-do-roofing-companies-face-during-storm-damage-repairs-in-2025/

- Florida Hardhat Law. (n.d.). Productivity Issues in Construction. https://www.floridahardhatlaw.com/productivity-issues-in-construction/

- LinkedIn. (2025). Survey Data Shows How Distributors Can Boost Productivity. https://www.linkedin.com/posts/roofing-supply-pro_survey-data-shows-how-distributors-can-boost-activity-7371528834921218048-RI6P

- GoCodes. (n.d.). Construction Productivity. https://gocodes.com/construction-productivity/