In roofing, it’s often the smallest details that have the biggest impact on a project’s outcome. Roofing accessories—including roofing ventilation, roof fasteners, and roof sealants—are frequently at the root of callbacks and costly jobsite delays. According to GAF, a leading roofing manufacturer, many callbacks are due to leaks and detailing errors, often caused by overlooked accessories or improper installation (gaf.com). The cost of such callbacks can range from $100 for simple cleanup to over $2,000 for major rework, which highlights the importance of getting accessories right the first time.

When proper attention is paid to these essential details, contractors can avoid common pitfalls and keep projects moving forward. For those seeking to streamline their next job, browsing the right roofing materials is the first step toward fewer headaches and a stronger reputation.

Why Accessories Stop Installs More Than Big Materials

It’s easy to focus on major roofing components, but missing or incorrectly installed accessories frequently become the reason a job stalls or a callback is required. This is reflected in the U.S. roofing accessories market, projected to reach $7.8 billion by 2025—a sign of the increasing attention contractors are placing on reliable accessory sourcing and management.

Industry experts note that accessory issues—such as improper fastener choice or missed ventilation requirements—can cause significant project delays and even warranty problems (roofingcontractor.com). Supply chain disruptions, particularly for fasteners and other essential items, have also led to notable slowdowns and site complications (agc.org).

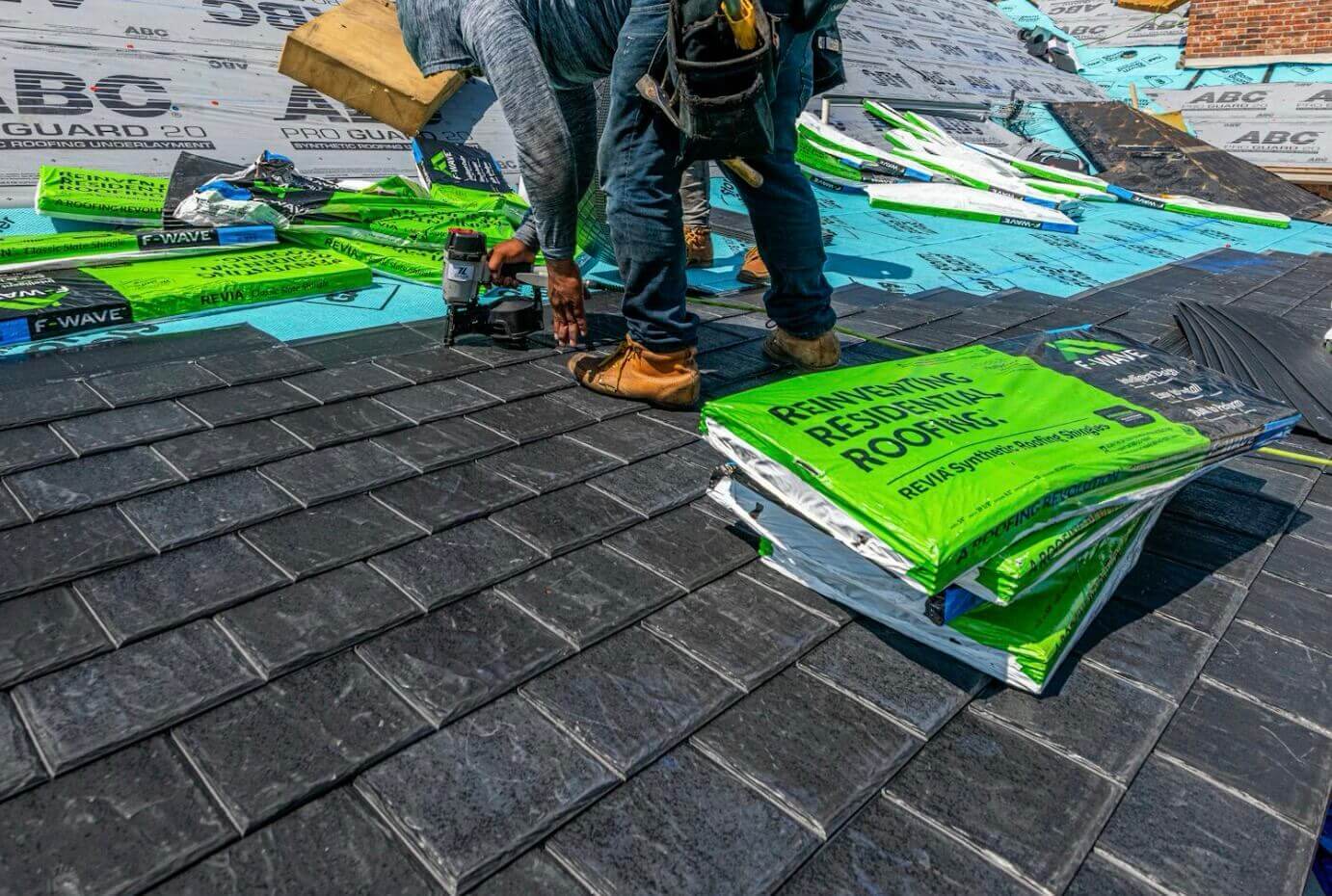

Preventing roofing callbacks often comes down to meticulous accessory planning and installation, rather than simply relying on the main system materials. One example: contractors are rapidly moving toward synthetic underlayment as a durable, time-saving alternative to traditional felt.

By making these small details a priority, contractors can minimize delays and avoid expensive, reputation-damaging rework.

Ventilation Basics to Confirm Before Ordering

It’s a question nearly every contractor faces: why is proper roof ventilation so critical, especially in Florida?

The reality is that adequate roofing ventilation is essential for regulating attic temperature and moisture, directly impacting the lifespan of your roof. The Florida Building Code mandates that enclosed attics and rafter spaces must have cross ventilation, with a net free ventilating area of at least 1/150 of the area of the space ventilated, or 1/300 with a vapor barrier in place. For Florida jobs, combining ridge and soffit vents is considered especially effective for moisture and heat control.

Insufficient ventilation can lead to moisture buildup, wood rot, and, ultimately, callbacks for costly repairs.

What really matters is confirming that ventilation systems meet both code and climate needs. Failing to do so risks not only structural damage but also non-compliance with state regulations.

Fasteners—What to Match to the System

Choosing the right roof fasteners is more than just a technicality—it’s a core part of durability and code compliance. Fasteners account for the largest share of U.S. roofing accessory demand, underscoring their vital role on every jobsite.

The Florida Building Code requires corrosion-resistant fasteners, especially in humid or coastal areas, to withstand the region’s harsh conditions. Stainless steel or other corrosion-resistant variants are mandated for long-term performance and to resist uplift in hurricane-prone zones.

When contractors neglect these requirements or use substandard fasteners, the likelihood of callbacks rises sharply. According to industry insights, using prefabricated accessories that come with appropriate fasteners reduces delays and helps every component meet regional standards (roofingcontractor.com).

Matching fasteners to the system and environment is a small step that prevents big problems.

Sealants and Coatings—Where They Show Up

Sealants and coatings often determine whether a roof stays watertight or ends up leaking. Sealant selection now includes asphaltic, polyurethane, and silicone options, as well as new hybrid sealants offering longer-lasting adhesion.

Improper sealant application is a well-known cause of leaks and callbacks in the roofing industry.

Leading manufacturers emphasize that leaks often occur around details like skylights or flashing—areas where sealant selection and application are critical (gaf.com). Not only can improper use of sealants lead to water intrusion, but it can also void manufacturer warranties and result in code compliance issues.

Always select sealants compatible with your roofing materials and follow manufacturer instructions to avoid unnecessary repairs.

The “Prevent the Second Trip” Accessory Checklist

A simple checklist can make the difference between finishing a job smoothly and having to return for forgotten details. Standard operating procedures—including checklists for each step of the installation—are recognized industry strategies for minimizing errors and reducing callbacks (gaf.com).

Post-project inspections using checklists help identify and address potential issues before they become expensive problems (rooferscoffeeshop.com). A comprehensive checklist should also cover material compatibility to prevent subtle installation issues.

For contractors who want to keep jobs on schedule, verifying every accessory before the crew leaves the site and planning for roofing material delivery are essential habits that pay off.

Delivery and Staging Note

Accessory planning and timely delivery are crucial to maintaining momentum on every roofing project. According to industry reports, delays in accessory availability—such as fasteners—have caused significant increases in project lead times and costs (agc.org).

Involving suppliers and manufacturers early, and scheduling delivery options for roofers, directly contributes to fewer callbacks and more efficient jobsite operations. Many suppliers now offer app-based ordering and delivery tracking to help keep projects organized—an advantage SYL Roofing Supply brings to Florida contractors.

When every detail is coordinated ahead of time, contractors can focus on what matters most: quality work, satisfied clients, and a reputation for reliability.

FAQ

What roofing accessories cause the most callbacks?

Ventilation mistakes, the wrong fasteners, and bad sealant detailing around penetrations and flashing are common sources of leaks and rework.

What ventilation items should I verify before ordering?

Confirm intake and exhaust components (soffit and ridge vents), net free area targets, and any job constraints like blocked soffits or complex rooflines.

What fasteners matter most for Florida and coastal jobs?

Corrosion-resistant fasteners are important in humid and coastal environments, and the correct type and length must match the roof system and deck for wind uplift performance.

How do I prevent a “second trip” for forgotten accessories?

Use a pre-load checklist that covers ventilation parts, compatible sealants, all fastener types, and detail items like drip edge, flashing, and boots before the crew mobilizes.

References

- GAF. (2025). How to Prevent Callbacks: 4 Tips for a More Effective Workforce. https://www.gaf.com/en-us/blog/residential-roofing/how-to-prevent-callbacks-4-tips-for-a-more-effective-workforce-281474979996320

- Roofing Contractor. (2025). It’s All in the Details: How to Avoid 4 Common Mistakes With Roofing Accessories. https://www.roofingcontractor.com/articles/101384-its-all-in-the-details-how-to-avoid-4-common-mistakes-with-roofing-accessories